Technology and

machinery

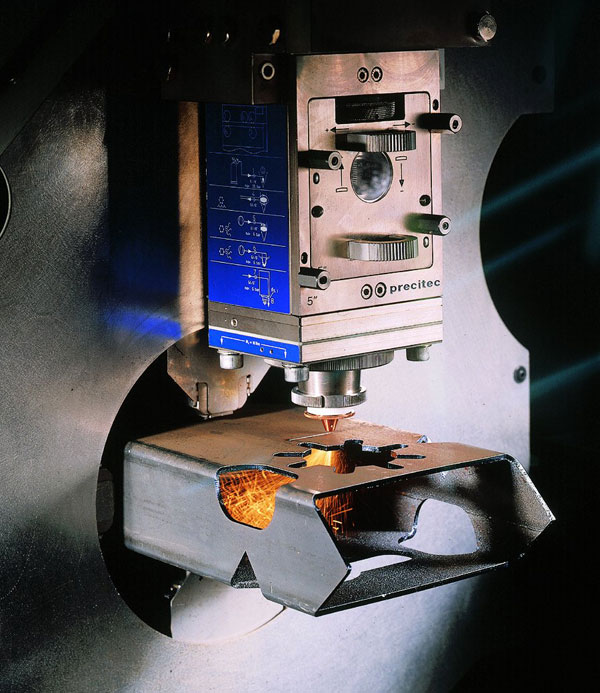

AR.MET. offers a wide range of machinery; alongside traditional equipment such as welders, punch presses, lathes, and milling machines, we also have state-of-the-art facilities including cutting-edge fiber laser cutting machines. These cutting-edge technologies allow us to ensure high standards of precision and quality.

- Laser tube

- Laser Fiber Amada Ensis

- Laser Amada Co2

- Folding

- Punching machine

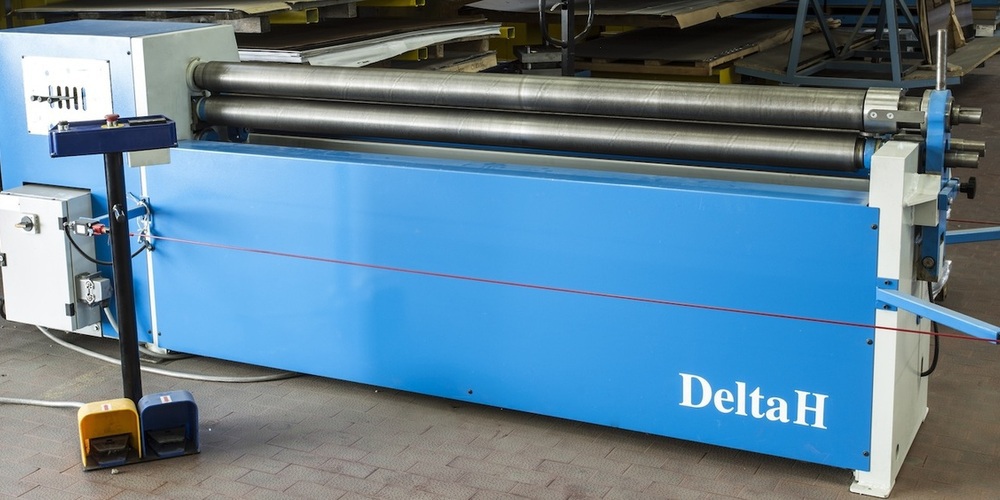

- Sheet metal calender

- Glazing and polishing machine

- Lathes and cutters

- Welding

AR.MET. offers its customers the efficiency and precision of the Adige LT712D laser tube, a production excellence made in Italy designed to work with tubes up to 152 millimeters in diameter. Equipped with a robotic cycle for bar management, this machinery represents the pinnacle of technology in the sector.

The laser tube is the optimal solution for manufacturing parts, both in the industrial and furniture sectors. Thanks to its versatility and high performance, it allows for impeccable results in terms of precision and quality.

AR.MET. also has the ENSIS 3015 AJ, a 3000 W fiber laser produced by Amada. This machine, thanks to its low center of gravity structure and high-torque motor movement system, performs precise and fast machining on various highly reflective materials such as copper, brass, and titanium. Paired with the 6-shelf AS L-UL robotic warehouse, which optimizes loading and unloading operations for both finished and to-be-processed pieces, it ensures a continuous and efficient production flow.

Amada CO2 lasers enable us to offer quality, flexible, and fast delivery services. The lasers in our facility have a working autonomy of 1500 mm in width and can essentially operate infinitely in length; the “scrolling” capability allows cutting sheets of any length with thicknesses up to 15 mm.

The use of laser cutting not only speeds up the delivery of significant batches of parts but also accelerates the production of small series and prototypes.

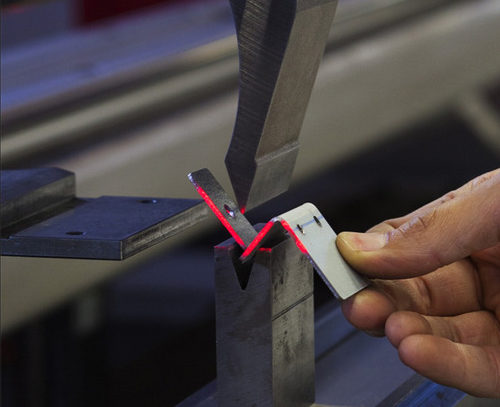

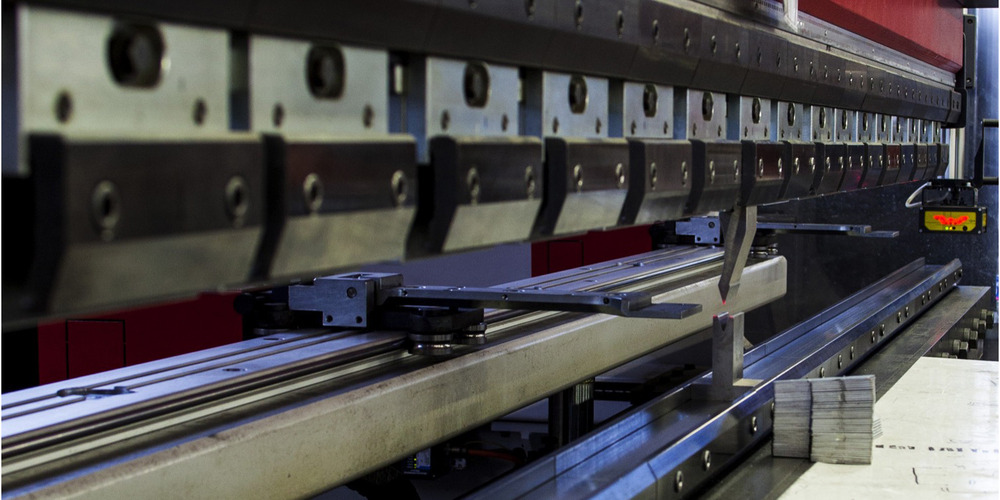

Our HFB press brakes represent the pinnacle of technology in bending process automation. The models in the HFB range, paired with cutting-edge software, enable precise working of all types of metals and plastics, up to a thickness of 10 mm and a length of 4150 mm.

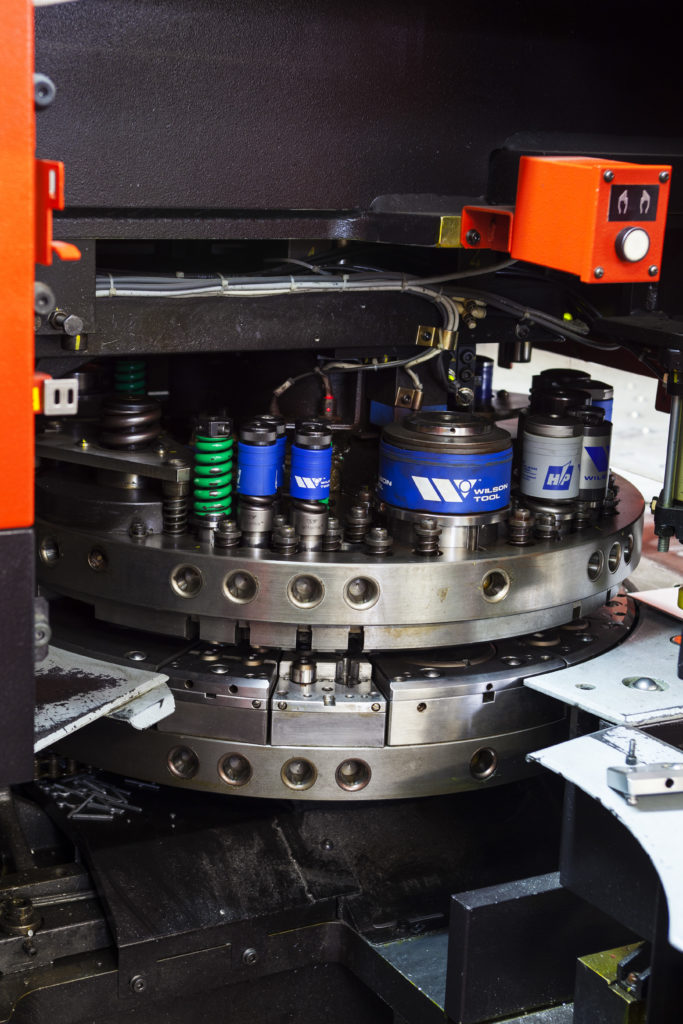

Thanks to the extensive range of punches, always readily available in the warehouse, we can quickly produce a wide variety of mechanical geometries upon request, significantly reducing production times and consequently costs for our customers. With a working area of 1250×2500 mm, the Amada Vipros 255 offers reliability and versatility, allowing the processing of sheets with a thickness of up to 3 or 4 mm, depending on the material.

The sheet metal calender has 3 rollers, enabling it to meet any curvature requirement. It can create both conical and cylindrical shapes on all types of sheets up to a width of 2150mm and a thickness of 2 or 3 mm depending on the diameter of the cone or circle you want to create.

The machine is equipped with a oscillating head with a wide working area of 1350 mm, perfect for performing satin finishes on stainless steel or ferrous materials. Thanks to its 5 motors, you can choose the desired finish, including different inclinations that give a unique and aesthetically pleasing touch to the items.

Lathes, milling machines, spot welders, and tube benders complete the range of machinery available

in the company. By doing so, we ensure that customers have a wide selection of services that fully meet their needs.

In our company, the art of welding is taken to the next level thanks to advanced laser welding technology. This innovative technique provides superior performance and unparalleled precision, ensuring impeccable results on a wide range of materials, from common metals to special alloys. We continuously invest in state-of-the-art equipment to ensure excellent results and compliance with the strictest specifications required by our customers.